Global supply chains are under pressure—volatile demand, long lead times, and razor-thin margins. At Radix, we blend AI/ML, statistical modeling, and mathematical optimization to turn that complexity into clear, executable decisions across planning, sourcing, production, inventory, logistics, and pricing.

Where supply chains leak value

- Forecast error & bias: promos/seasonality under-modeled

- Working capital drag: one-size-fits-all policies, stale safety stocks

- Planning misalignment: procurement–production–sales out of sync;

- Factory inefficiency: excess changeovers, hidden bottlenecks, yield/quality losses, suboptimal plant locations

- Risk & volatility: commodity swings, regulatory shocks, weak scenario planning.

Our toolkit

- Predictive AI/ML for demand, lead times, price trends, and quality.

- Optimization models (linear, mixed-integer) for procurement, production, network flows, and inventory policies.

- Simulation to stress-test designs and operating envelopes before you spend a dollar.

- Decision software: APIs, data lakes, dashboards, and workflow apps that fit your tech stack.

From data to decisions – A few real cases

- Spare Inventory Optimization for Mining Corporation with 9 mines network

- ~$80Mn (~20%) reduction in inventory value

- a tailored ROP/EOQ policy—selected via an ML decision tree over demand profiles while maintaining SLAs, and reduce ordering/holding costs as policies updated the MRP master

- Procurement & Production Planning for Global Cocoa Manufacturer

- stock reduced from 24 to 7 months with zero unusable stale beans

- an integrated annual/monthly/daily plan

- minimized purchase, transit, and holding costs while respecting quality specs

- Freight Pricing for Energy & Logistics Solutions Company

- achieved ~95% accuracy on OD-date-equipment quotes

- an ensemble of ~500 models, governed by lane-aware selection rules and deployed via MLflow

- equipping agents to post competitive load-board fares, even on sparse lanes

- Petrochemical Price Forecasting for Independent Commodity Intelligence Services

- forecasting models with >95% accuracy

- combined uni/multivariate approach including a Market Sentiment Index

- 1–12-months outlook and driver insights for planning and hedging

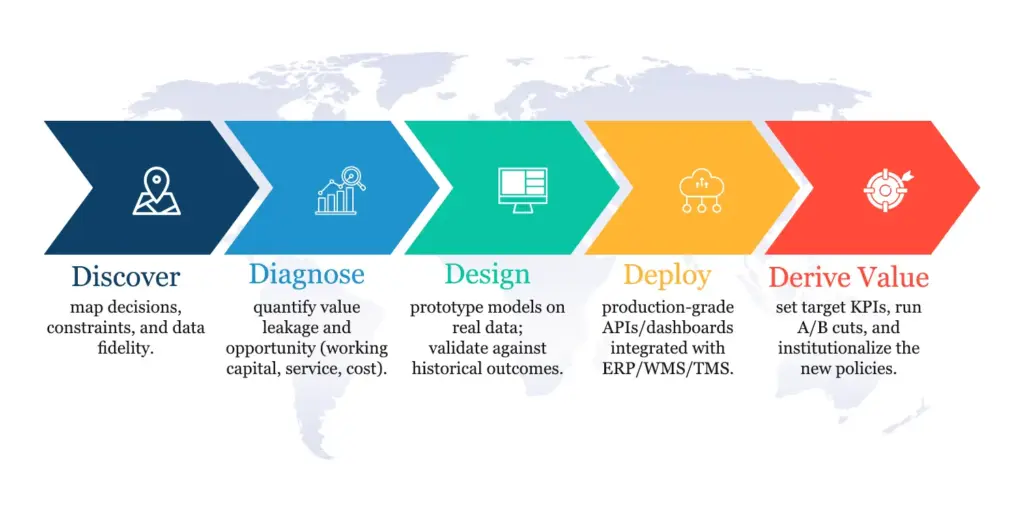

The way we collaborate

What’s in it for you

- Lower working capital with service levels held or improved.

- Faster, feasible production plans that respect business constraints.

- More consistent, explainable pricing decisions in thin data environments.

- Better hedging and procurement timing with credible price signals.

If you’re wrestling with inventory bloat, opaque logistics pricing, or fragile planning cycles, let’s turn your supply chain into a decision-ready engine.